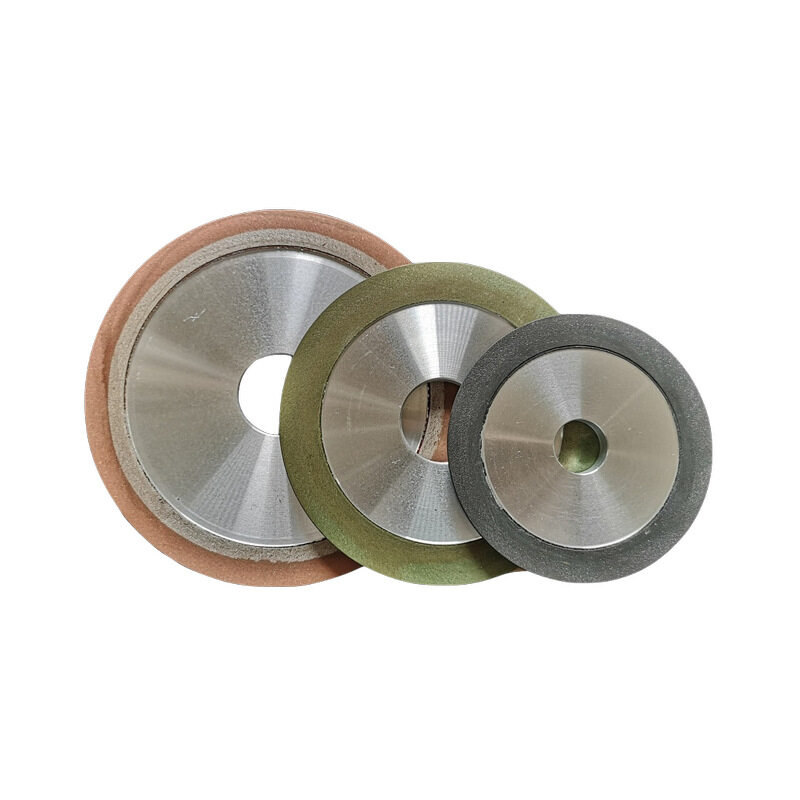

Grinding wheels of various sizes

Various types of grinding wheels

| Product Name | Small grinding wheel | Washer type | Small grinding wheel |

| Material | Diamond | exterior finishes | plating |

| Color | black | Size | custom made |

| MOQ | 3000M/Each size | country of origin | China |

| Payment | T/T. other | Packing | As customer required |

The structure of the grinding wheel includes three major elements: abrasive, binder and pores. The abrasive directly grinds the workpiece, the binder generates the bonding force between the abrasive particles and keeps the grinding wheel rotating safely at a certain speed, and the pores help to remove the grinding chips to maintain the grinding effect.

The characteristics of the grinding wheel depend on factors such as the abrasive, binder, the organization, hardness and shape of the grinding wheel. Each grinding wheel has a certain range of application according to its own characteristics. For example, a harder grinding wheel should be used when grinding soft materials, while a soft grinding wheel should be used when grinding hard materials. In addition, the grinding wheel has "self-sharpening", that is, the grinding force will increase after the abrasive grains are blunted, causing the abrasive grains to break or fall off, and the sharp edge will be exposed again. This characteristic allows the grinding process to proceed normally within a certain period of time, but manual grinding is required after a certain period of time.

During use, grinding wheel dressing is an essential step. Dressing technology can produce a new sharp profile while ensuring consistent accuracy. Selecting reasonable dressing parameters (such as dressing speed ratio) has a significant impact on the dressing quality of the grinding wheel, and directly determines the grinding wheel morphology and profile accuracy.

In order to improve the service life and working efficiency of the grinding wheel, an impregnating agent can be used to fill the air gap of the grinding wheel, such as sulfur impregnation, paraffin impregnation, etc., to increase the lubricity of the grinding wheel. In addition, the safe use of the grinding wheel is also very important. When installing the grinding wheel, ensure balance and conduct a test run to check for vibration or other adverse phenomena. Strictly follow the safety operating procedures during operation, such as using a shield to prevent debris from scattering and protect the operator.

In short, as an indispensable tool in mechanical processing, the correct selection, use and maintenance of the grinding wheel are crucial to improving processing efficiency and ensuring processing quality.

|

Q: What's your MOQ? A: If we have the products in stock, it will be no MOQ. If we need to produce, we can discuss the MOQ according to customer's exact situation. |

|

Q: How long is your delivery time?A: The general delivery time is 30-45 days after receiving your order confirmation. Anther, if we have the goods in stock, it will only take 1-2 days. |

|

Q: What is your term of payment? A: 30% down payment before producing and 70% balance payment before shipping. |